E85 Compatibility: Let’s Clear the Air

NOTE:This article applies ONLY to vehicles with an eFlexFuel E85 kit installed. Stock vehicles that are not rated for E85 cannot run E85 unless an eFlexFuel kit has been installed!

Have you heard claims like “E85 will melt your fuel lines,” “ruin your engine oil,” or that you need to replace your entire fuel system to use it? Here’s the truth: None of that is true for vehicles approved for eFlexFuel kits.

Despite what you might’ve read online or heard from a traditional mechanic, most modern vehicles are already equipped with components that are fully compatible with ethanol. Once an eFlexFuel kit is installed, your vehicle can safely run E85 without any major modifications.

Today’s automotive materials and engine oils are designed to handle ethanol reliably. The myths surrounding E85 mostly stem from outdated information that applies to vehicles over 35 years old.

This page provides a fact-based technical overview to help you understand what’s really involved in converting your vehicle to run E85. Our goal is to address common concerns and help you make an informed decision about upgrading with eFlexFuel—so you can enjoy the flexibility of using E85, gasoline, or any blend of the two.

Quick Navigation

- At a Glance: Ethanol Compatibility

- Debunking Common E85 Myths

- Materials Compatibility: Modern Fuel Systems and Ethanol

- E85 & Engine Oil Compatibility

- Fuel System Capacity: Stock Fuel Injectors and Pumps

- The E85 Advantage: Cleaning Benefits

At a Glance: Ethanol Compatibility

- ✅ Your vehicle already runs on ethanol blends. Most gasoline sold world wide contains 10% ethanol (E10).

- ✅ Modern fuel systems are ethanol-ready. Federal regulations in 1994 and 2001 led to improved fuel system materials that support ethanol use.

- ✅ Engine oils have been E85-compatible since 2010. The American Petroleum Institute (API) updated its standards to include E85 testing.

- ✅ Stock fuel injectors and pumps are compatible. eFlexFuel-approved vehicles have been benchmarked to ensure safe and efficient E85 operation.

Debunking Common E85 Myths

Myth 1: "E85 Will Melt Your Fuel Lines" ❌

Reality: Modern fuel lines are made from advanced polymers and composites that are highly resistant to ethanol.

Myth 2: "E85 Damages Engine Oil" ❌

Reality: Today’s engine oils are formulated to work with ethanol. Since 2010, API SN standards include:

Reality

- Emulsion retention testing with E85

- Enhanced additive packages for ethanol protection

- Phosphorus retention requirements to protect catalytic converters

Myth 3: "E85 Causes Catastrophic Phase Separation" ❌

Reality: Phase separation only occurs under extreme conditions involving significant water contamination—levels even higher than what gasoline can tolerate. Under normal driving conditions:

- E85 can absorb up to 4% of its volume in water before phase separation occurs. For example, with 15 gallons of fuel, it would take over 75 ounces of water to trigger separation—that’s a substantial amount.

- In comparison, regular E10 gasoline separates at just 0.5% water content.

- This means E85 is actually more water-tolerant than standard gasoline.

Myth 4: "E85 Corrodes Fuel System Components" ❌

Reality: Modern fuel system components are built using advanced materials—polymers, composites, and coatings—that are highly resistant to ethanol. These materials are specifically designed to withstand ethanol exposure without degradation.

Materials Compatibility: Modern Fuel Systems and Ethanol

Note: This section focuses on the physical compatibility of fuel system materials with ethanol. Flow rates and air-fuel adjustments are managed by the eFlexFuel kit.

Concerns about ethanol damaging fuel systems are based on outdated information. Materials like natural rubber hoses and cork gaskets, which were vulnerable to ethanol, haven’t been used in mainstream fuel systems for decades.

As ethanol became more common in commercial gasoline starting in the 1980s, automakers began using advanced polymers and composites that offered better durability and chemical resistance. This shift was accelerated by the rise of Electronic Fuel Injection (EFI) and stricter evaporative emissions regulations.

🚗 The Fuel System Durability Revolution (1994–2001)

Federal regulations pushed manufacturers to adopt more robust fuel system materials:

1994–1996: Tier 1 Standards

Introduced tighter limits on hydrocarbon emissions and fuel system integrity, leading to the use of low-permeation, ethanol-resistant materials.

1999–2001: National Low Emission Vehicle (NLEV) Program

Enforced stricter long-term emission controls, prompting widespread adoption of ethanol-compatible fuel system components.

2001+: CAP2000 Certification Program

Required enhanced durability testing, including material resistance and low permeability—further solidifying ethanol tolerance in modern vehicles.

✅ The Outcome

By 2001, nearly all vehicles sold in the U.S. featured fuel system materials that were:

- Highly durable

- Low in permeation

- Chemically resistant to ethanol

Bottom line: Most vehicles from 1994 onward, and virtually all from 2001 and newer, are equipped with fuel systems that are fully compatible with ethanol blends, including E85.

The Science Behind Materials Compatibility

To meet the stringent requirements of federal emissions standards like NLEV and CAP2000, automakers adopted advanced fuel system materials that—by design—offer excellent ethanol compatibility:

- Low-permeation polymers, required to reduce evaporative emissions, naturally resist ethanol penetration.

- Advanced elastomers, chosen for durability, provide strong chemical resistance to polar solvents like ethanol.

- Composite fuel rails and tanks, used for weight reduction and durability, are inherently ethanol-resistant.

Although no regulation explicitly mandated ethanol compatibility, the materials and engineering solutions developed to meet these standards incidentally provided the exact chemical properties needed for safe ethanol use.

So What Does This Mean for Your Vehicle?

While these regulations were aimed at reducing emissions, they led manufacturers to use materials that are inherently resistant to ethanol. The same properties—low permeation and high durability—also make these components ideal for handling E85.

✅ 2001 and Newer Vehicles

If your vehicle was sold in the U.S. in 2001 or later, its fuel system is highly ethanol-tolerant thanks to these regulatory-driven advancements.

Vehicles from 2001 onward that are eFlexFuel-approved can safely run E85, gasoline, or any blend of the two once an eFlexFuel kit is installed.

✅ 1994–2000 Vehicles

Vehicles from this era likely have ethanol-tolerant fuel systems, though regulations were less strict.

If eFlexFuel-approved, these vehicles can also run E85 safely. We recommend inspecting fuel system components for signs of wear—such as cracking or swelling—during installation and routine maintenance.

⚠️ 1993 and Older Vehicles

Ethanol compatibility is less certain for vehicles built before 1994, as regulations didn’t yet drive material upgrades.

If you plan to install an eFlexFuel kit, consider replacing key components like fuel lines, filters, and pumps as a precaution. Regular inspections are advised to ensure safe operation with E85.

Supporting Evidence: NREL’s 2021 Global Study

The National Renewable Energy Laboratory (NREL) conducted a comprehensive study in 2021 evaluating ethanol-blended fuel compatibility across vehicle generations. The findings showed a strong correlation between stricter emissions standards and improved ethanol tolerance in fuel system materials.

While the study didn’t directly assess E85 use in non-flex-fuel vehicles, the materials science and regulatory timeline strongly support the conclusion that modern vehicles are well-equipped to handle ethanol blends.

Thousands of eFlexFuel Kits Installed Worldwide

Since 2012, eFlexFuel has delivered E85 flex-fuel systems globally. With data from thousands of real-world installations, we estimate our customers have driven over 2 billion miles without any known material compatibility failures—making this the most comprehensive evidence to date supporting E85 use in modern vehicles.

E85 & Engine Oil Compatibility

The 2010 API Engine Oil Breakthrough for Ethanol Fuels

In 2010, the American Petroleum Institute (API) introduced the API SN engine oil standard, specifically designed to support ethanol-blended fuels—including E85. This update was a direct response to the growing use of ethanol in gasoline, and all subsequent API standards have continued to include these ethanol-related improvements.

🔧 Key Enhancements in API SN for Ethanol Compatibility:

- 51% better piston deposit protection, crucial for ethanol fuel systems

- Enhanced compatibility with ethanol blends up to E85

- Improved emission system protection, including phosphorus retention

- Phase separation prevention, verified through emulsion retention testing

The API SN specification includes ASTM D7563 emulsion retention testing, where engine oil is mixed with 10% water and 10% E85 to ensure no separation occurs—demonstrating its resilience in real-world conditions.

The Bottom Line

Modern, high-quality engine oils have been formulated for E85 compatibility since 2010. By following your vehicle manufacturer’s recommended oil change intervals and using reputable engine oil, you can confidently run E85 without any added risk to your engine.

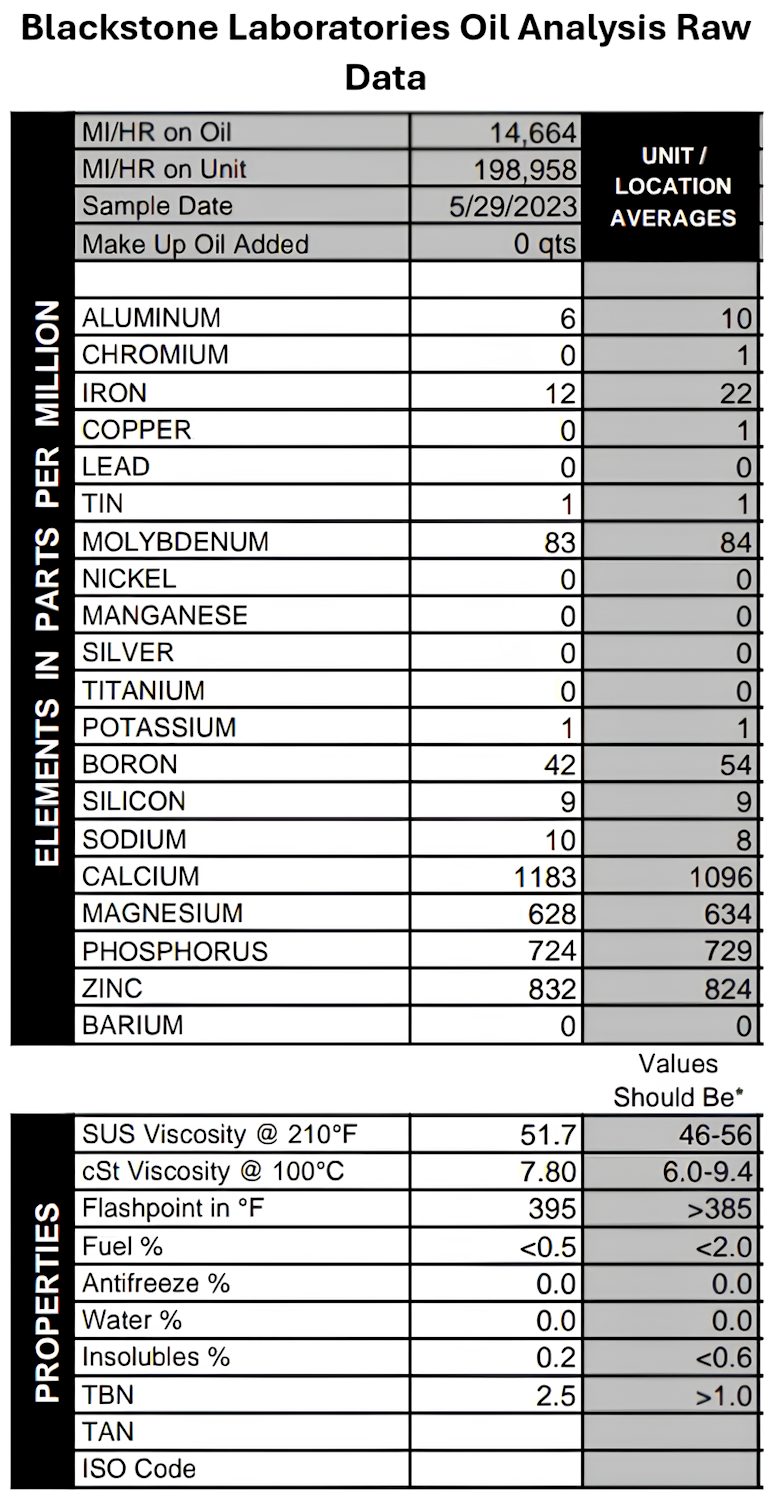

Real-World Proof: Blackstone Oil Analysis

Independent testing by Blackstone Laboratories confirms that E85 does not accelerate engine wear or degrade oil quality when using modern, reputable engine oils. Their analysis supports the conclusion that E85 is safe for long-term use in vehicles equipped with compatible systems.

| Vehicle | 2015 Toyota Prius with eFlexFuel E85 Kit Installed |

|---|---|

| Miles on Vehicle | 198,958 |

| Miles Between Oil Change | 14,664 |

| Fuel | Exclusively E85 |

Key Findings from the Oil Analysis:

✅Clean Oil Performance:

- Aluminum: 6 ppm- Well within normal range (typical limit ~10-13 ppm)

- Iron: 12 ppm- Excellent levels indicating minimal engine wear

- Molybdenum: 83 ppm- Stable additive levels showing oil integrity

✅No Fuel Contamination:

- Fuel dilution: <0.5%- Extremely low, indicating proper fuel combustion

- No abnormal wear patternsdespite extended oil change interval and high-mileage driving

- TBN of 2.5- Sufficient alkaline reserve for continued protection

What This Means: After 14,664 miles of driving with E85, the oil analysis showed that the engine oil retained its protective qualities with no signs of ethanol-related degradation or contamination. This directly debunks the myth that E85 harms engine oil and confirms that modern, high-quality oils provide reliable lubrication when using E85.

Fuel System Capacity: Stock Fuel Injectors and Fuel Pumps

eFlexFuel kits are designed to operate seamlessly with your vehicle’s stock fuel injectors and fuel pump. Although E85 fuel demands higher fuel delivery, most OEM systems have sufficient capacity to support E85 usage when paired with eFlexFuel technology.

How eFlexFuel Enables Safe E85 Use with Stock Components

We’ve built a robust compatibility database to ensure safe and reliable E85 operation. When a vehicle is listed as compatible, it means:

- ✅Stock fuel injectors can meet the increased duty cycle demands within safe limits.

- ✅Stock fuel pump delivers the necessary flow rate and pressure for E85.

- ✅The complete fuel delivery system maintains proper pressure and flow across the engine’s operating range.

- ❌No aftermarket injectors or fuel pump(s) are required..

Our database is developed using strict validation criteria:

- Verified injector flow rates: We confirm that stock injectors can handle E85 before approving any vehicle.

- No guesswork involved: If your vehicle is listed, its stock components have already been proven to support E85 reliably.

- Clear exceptions: In rare cases where upgrades are needed, we always disclose this upfront.

Engineering Synergy Between eFlexFuel and OEM Fuel Systems

Modern fuel systems are engineered with significant overhead to handle real-world conditions. This built-in flexibility allows for E85 conversion without major modifications.

eFlexFuel kits take advantage of this reserve capacity, offering precise control and optimization for E85 use. Instead of requiring costly aftermarket upgrades, we utilize the robust capabilities already present in your vehicle’s fuel system—designed to accommodate varying fuel types and operating demands.

The E85 Advantage: Fuel System Cleaning Benefits

E85 isn’t just a performance fuel—it also acts as a natural cleaner for your vehicle’s fuel system, offering several reliability and maintenance advantages.

✅ Carbon Deposit Removal

Ethanol in E85 helps break down and remove harmful buildup throughout the fuel system:

- Dissolves carbon deposits from fuel injectors and intake valves

- Eliminates gum and varnish from fuel system components

- Cleans more effectively than conventional gasoline

- Breaks down long-standing deposits accumulated over time

✅ Enhanced Fuel System Performance

A cleaner fuel system translates into better overall performance

- Clean injectors improve fuel atomization

- Reduced carbon buildup boosts engine efficiency

- Improved fuel flow through cleaned components

- Restores proper spray patterns in previously clogged injectors

Why E85 Cleans Better Than Gasoline

🧪 Chemical Properties

Ethanol’s unique chemical makeup gives it superior cleaning capabilities:

- Acts as a polar solvent, dissolving water, acids, and oxidation byproducts

- Contains 35% oxygen, compared to just 2–4% in oxygenated gasoline, promoting more complete combustion

- Its molecular structure allows it to penetrate and dissolve deposits that gasoline cannot reach

🔬 Solvent Action

Ethanol’s solvent properties make it highly effective at cleaning:

- Dissolves gums, varnishes, and carbon deposits caused by gasoline degradation

- Functions as a co-solvent, removing both polar and non-polar contaminants

- Offers significantly better cleaning efficiency than gasoline

📈 Long-term Fuel System Health

Regular use of E85 contributes to sustained fuel system cleanliness:

- Helps prevent future deposit formation

- Maintains clean fuel system operation over time

- Reduces reliance on chemical fuel system cleaners and additives